Solar Pumps: A Sustainable Solution for Water Needs in Southern Africa

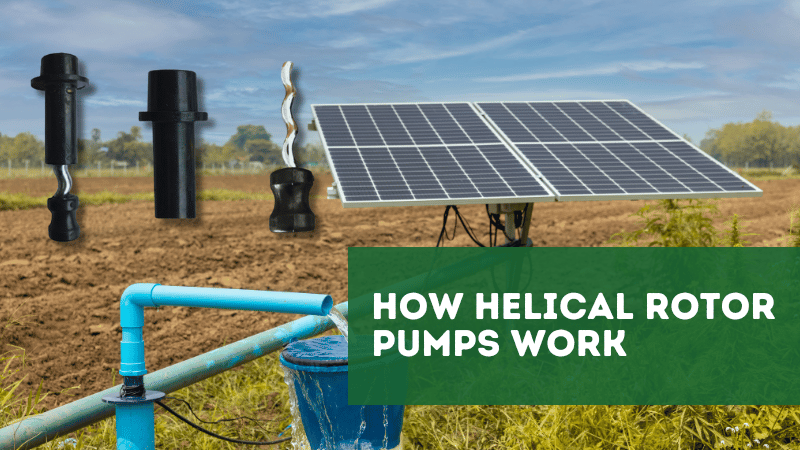

Solar pumps have become a sustainable solution for water pumping in Southern Africa, particularly in off-grid and remote areas. Countries like South Africa, Botswana, Namibia, and Zimbabwe have adopted this technology because of their sunny climates and groundwater typically found at depths of 30 to 200 meters. Among the various designs, submersible solar pumps with a helical rotor (screw) stand out for their efficiency and versatility. But how exactly do these pumps work, and what makes the helical rotor (screw) design so effective?

What is a Solar Pump?

A solar pump uses solar energy, typically captured through solar panels, to pump water. These pumps are widely used in agriculture, livestock watering, and domestic water supply. They are particularly valuable in regions where grid electricity is unreliable or non-existent.

Submersible solar pumps operate underwater, typically in boreholes or deep wells. This design benefits areas where surface pumps cannot reach deep water sources, which is common in many parts of Southern Africa.

Understanding Helical Rotor (Screw) Technology

The helical rotor (also known as screw or worm) design is a key feature of some submersible solar pumps, especially those used for low-flow and high-head applications. The rotor (screw) is a screw-like component that rotates inside a stator, a stationary part with a helical cavity. As the rotor turns, it creates a continuous flow of water, even at varying speeds.

This design allows for efficient water pumping from deep sources, even when solar energy supply fluctuates due to changing weather conditions.

How Does a Submersible Solar Pump with Helical Rotor (Screw) Work?

Submersible solar pumps with helical rotors start with solar panels capturing sunlight and converting it into electricity. This electricity powers the motor, which submerges with the pump in a borehole or well. The motor then rotates the helical rotor inside the pump.

As the rotor spins, it moves water through the pump in a continuous and smooth flow. The helical shape of the rotor creates cavities that transport water from the pump’s inlet, deep within the well, to its outlet at the surface. Unlike pumps that rely on high-speed impellers, the helical rotor design is more effective at pumping water from great depths, making it ideal for submersible applications.

Advantages of Submersible Solar Pumps with Helical Rotor (Screw)

Submersible solar pumps with helical rotor technology offer several advantages:

- Efficiency in Low-Flow and High-Head Conditions: These pumps perform well in boreholes ranging from 20 to 180 meters deep. They are suited for applications requiring water to be lifted from deep boreholes or wells, even with minimal water flow. For deeper boreholes or higher water needs, multi-stage impeller pumps may be a better option.

- Durability and Maintenance: The robust design of the helical rotor pump limits the exposure of moving parts to wear and tear. This results in lower maintenance costs and a longer service life. The helical rotor, being the component most likely to wear out, can be easily and inexpensively replaced to maintain optimal pump performance.

- Maintenance and Water Quality: The quality of the water being pumped significantly impacts the longevity of these pumps—cleaner water generally leads to a longer pump life. If the water contains sediment, it’s advisable to pull the pump every six months for cleaning. Replacing the helical rotor annually can also increase the overall lifetime of the pump. This design protects the motor, as the rotor absorbs most of the wear. Replacing the helical rotor is relatively inexpensive, costing about $20 (R300). Regular maintenance and clean water will maximize the pump’s lifespan.

Applications and Benefits

Submersible solar pumps with helical rotor technology are commonly used in agriculture for irrigation, in livestock watering systems, and for providing potable water in rural communities. Their ability to operate efficiently on solar power makes them an environmentally friendly choice, reducing dependence on fossil fuels and minimizing carbon footprints.

Economically, these pumps can lead to significant cost savings in regions where electricity is expensive or unavailable. The initial investment in solar pump technology is often offset by long-term energy cost savings and low maintenance requirements.

Conclusion

Submersible solar pumps with helical rotor technology offer a smart and sustainable solution for borehole pumping needs. Their efficient design, combined with the use of renewable solar energy, makes them an attractive option for various applications. As demand for eco-friendly solutions grows, these pumps will likely play a crucial role in addressing Southern Africa’s water challenges.